A few years ago, a car manufacturer customer sitting opposite Ryan Evans made an unusual request. "He wants to know how we can accurately predict the power consumption of our bearings in their applications." Evans said. He is currently responsible for the bearing research and development of Timken Company. The SYBER bearing performance prediction software of Timken Company can be used not only for bearing selection analysis, but also for estimating torque and power consumption. However, for the customer's application, the customer seems to want to obtain more reliable prediction results.

The power consumption of bearings involves many disciplines from fluid mechanics to solid mechanics, thermodynamics and heat transfer. Bill Hannon, basic product scientist of Timken Company, said: "This is to study how the properties of materials (whether steel or liquid) will change when encountering high pressure, high speed and high temperature in friction contact."

For example, a tapered roller bearing may contain 15 rollers, which are the contact points. To calculate torque, you must consider how all these different contact points will respond to the load and speed of a particular application. For example, whether the material will bend under these contact points, or whether the lubricating oil between them will be subject to shear effect.

"It will be a daunting task to consider all the above factors to obtain the total power consumption or torque performance of the bearing." Evans said.

Talking about bearing efficiency beyond bearing

However, similar customer requirements continue to emerge. "Our customers are under pressure to improve fuel efficiency." Evans said. From tractors to delivery trucks to luxury cars, manufacturers of all kinds are turning to electric vehicles. In order to minimize battery weight and maximize vehicle mileage, they must minimize friction at every point in the machine.

Bearing efficiency is one of them, and Timken began to design energy-saving bearings decades ago. In 1975, the American Corporate Average Fuel Economy (CAFE) regulation required to improve the fuel efficiency standard. Timken's fuel saving bearings played an important role in the design of traditional and hybrid electric vehicles.

Bob Sadinski, the senior product development engineer of Timken, once worked directly with customers on the design of the power transmission system to help develop the oil saving bearing (ePDFE) of Timken.

He said: "At Timken, we have always been concerned about the friction and energy loss during the bearing rotation. In order to further improve the bearing efficiency, we need to understand the entire system, including the customer's lubrication system."

Understand the properties of fluids

"Customers want to use a lighter, lower viscosity lubricant, but this will cause hardware problems." Sadinski said. In order to help customers optimize the combination of bearing lubricants to achieve maximum efficiency, Timken's team needs to combine bearing technology with rheological research. Rheology is a branch of physics that studies liquid flow.

Hannon said: "When I touch some lubricating oil with my hand, I can rub my fingers to feel it. I think it is soft and light. But in the bearing, it is not at all. When the rolling element meets the raceway, the contact pressure is very high, the oil film is very thin, and the lubricating oil will almost become solid."

In other words, as the acting pressure, temperature and shear rate of the contact point increase to an extreme level, the viscosity or flow resistance of the lubricating oil will change strangely. To make matters worse, petrochemical industry has undergone great changes in the past decade. "Previously, there were only a few viscosity regulators, but now there are hundreds of them." Hannon said.

To predict bearing efficiency, it is important to understand the nature of the exact fluid, oil, or grease in each application. Hannon said that in an ideal environment, the application engineer can measure the lubricant performance at a pressure of three kilopascals or 435000 pounds per square inch.

"Nobody can do that," he said. "There are few laboratories in the world that can measure values greater than 1000 MPa."

In addition, he said, engineers also need to understand how the viscosity of lubricating oil changes with the applied pressure, temperature and shear force. "We know that there are only three places in the world that can do this." Hannon said: Georgia Tech, INSA in Lyon, France, and now Timken.

A laboratory for scientists to observe lubricating grease

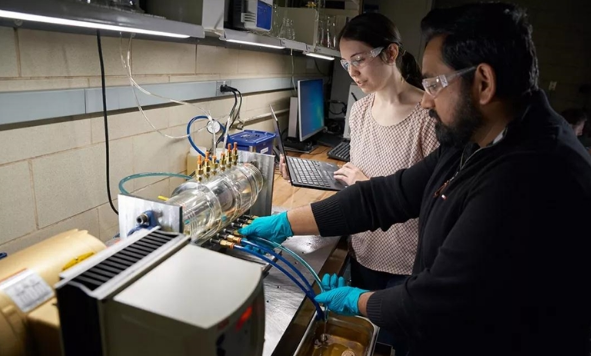

Hannon said that the rheology laboratory of Timken Company is based on the theory that allows the company to improve the torque prediction model by using physical principles. To test this theory, the R&D team asked Georgia Tech researchers to measure the viscosity of the two oils. Subsequently, Timken researchers input the measurement results into their models, which proved that they could indeed make more accurate bearing efficiency predictions.

"At that moment, we decided to invest." Hannon said. Today, Timken's rheology laboratory is equipped with two falling body viscometers, which can measure viscosity and density under various pressures and temperatures. With the Kuyt viscometer, our team can also measure the lubricant's response to high shear rates.

Hannon also said that the laboratory also has some very practical equipment, including: a Fourier transform infrared spectrometer, which can help our team identify unknown fluids; An energy dispersive X-ray spectrometer, which can help our team identify the components in the liquid that wear the equipment; A Karl Fischer titration device, which can detect the moisture in the oil; And other "equipment that allows us to analyze grease".

Let theory drive the model

Using these devices, Hannon and Sadinski can measure a single fluid and use the data to build a new mathematical model, allowing them to predict conditions in an infinite range of multidimensional spaces.

"We have returned to the principles of fluid mechanics, so it is the theory that led to the establishment of our model." Hannon said. Studying things from the first principle level allows our team to predict friction, not just measure friction. At the same time, he thought: "With the help of rheology laboratory, we will be able to get closer to reality, reduce assumptions, and then make our simulation closer to the actual application conditions."

Evans said, "These new measurement technologies enable us to measure lubricating oil in an unprecedented way. We insert these data into the mathematical model and then help us predict the performance of the fluid in the bearing under high pressure and high shear conditions. This information enables us to better predict the overall torque or power consumption performance."

From laboratory to customer design table

After the R&D team adds the new mathematical model to Timken's SYBER system, application engineers around the world can make more accurate power consumption estimates. "SYBER helps us obtain information and knowledge from the laboratory and then pass it on to customers." Evans said.

Hannon and Sadinski have kept close contact with lubricant manufacturers, and lubricant manufacturers are increasingly accepting various fluids. Hannon said, "In this way, lubricant and bearing may be used together in the future. In the rheology laboratory, we are sure that this can be done, so now all of us are working hard, including lubricant manufacturers, bearing manufacturers and customers."