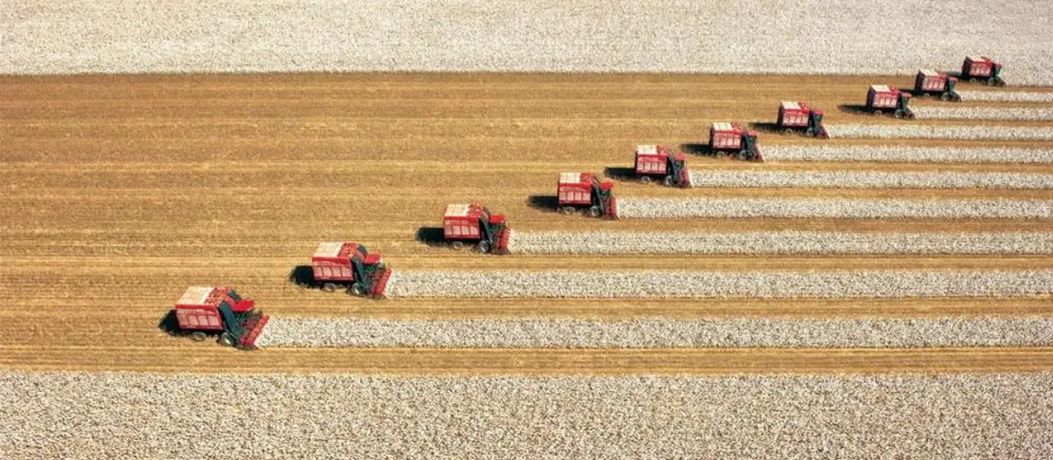

Look at the billowing golden wheat waves and enjoy the impressive harvest scene of China!

By the end of June, the national "Three Summers Conference" had ended perfectly. According to statistics, this year's "wheat summer harvest" has more than 600000 wheat harvesters participating in the operation, and the mechanized wheat harvest is 298 million mu, with the mechanization rate exceeding 98%.

If agriculture is stable, the world will be safe. SKEFL is well aware of the importance of agricultural machinery as a national strategic industry. Among the key parts of agricultural machinery, there are special bearings for SKEF agricultural machinery everywhere. Every busy season, SKF special bearings for agricultural machinery will shoulder the mission of "not lying down" in the harsh environment of high temperature, dust and high speed, and contribute to the upgrading of China's agricultural machinery industry.

"Obstacles" affecting equipment performance

After the "three summers", look forward to the "three autumn". As one of the important cash crops in China, cotton production and sales volume has ranked first in the world for ten consecutive years. According to the National "Fourteenth Five Year Plan" for the Development of Planting Industry, the cotton harvesting rate should reach more than 70%, and break the dependence on imported cotton pickers, so as to achieve independent research, development and manufacturing of domestic high-end cotton pickers.

The cotton picking environment is full of dust. During the busy harvest season, in order to "compete for speed and benefit", the cotton picker needs to carry out continuous operation with high intensity while ensuring the net picking rate. However, domestic cotton pickers are prone to failure under high load working conditions and delay the harvest progress.

Our customer is confronted with such problems. The main product developed by this customer is the internationally advanced 6-row packing cotton picker. The bearing failure rate of the main fan, the key part of the prototype, is as high as 30%. The frequent failures of the equipment have become a major problem puzzling customers, which has seriously hit customers' confidence in mass production of cotton pickers.

With more than 80 years of experience in the agricultural machinery industry, SKEFL quickly determined that the root cause of the problem was: how to ensure the reliable operation of the bearing under the harsh working environment of high temperature, high pollution and high speed?

With the support of SKF Global Agricultural Machinery Application Center and the local laboratory, we customized a set of high-performance cotton picker special bearings for the customer, which were verified on the test bench.

Skiff's professional ability in the field of agricultural machinery has won the absolute trust of customers, who directly assembled a full set of special bearings for Skiff agricultural machinery on 120 cotton pickers.

The results were encouraging. The bearing failure rate of 120 cotton pickers was reduced from 30% to 0%. The maintenance cost of cotton pickers was saved by 185600 yuan/set.

Reliable operation boosts the upgrading of modern agriculture

Due to different crops, farmland scale, geographical location, climate and soil structure, each farmland operation has its own particularity. In addition to cotton pickers, SKF provides customized bearing solutions for all kinds of agricultural machinery, giving full play to the advantages of high bearing capacity, strong sealing and maintenance free of bearings, to ensure efficient and reliable operation of agricultural machinery.

SKF has a strong global R&D and production capacity of agricultural machinery bearings, and has established an industry-leading mud testing center in Xinchang Plant. In addition, in recent years, it has also continued to increase investment in new production lines, striving to provide advanced and reliable products and strong technical support for Chinese agricultural machinery customers, helping customers create more value, promoting the upgrading and transformation of China's agricultural machinery industry, and ensuring the country's food security strategy.